In 2024, we deepened our commitment to the principles of circularity throughout our entire value chain. Our approach is to evaluate the product life cycle, from product conception to end-of-life, and examine the environmental impacts at each stage. We do this by developing circular economy strategies that reduce our reliance on virgin materials, keep products in service longer, reduce waste and create new strategic business opportunities.

Our six strategic circularity pillars are:

- Sustainable & Circular Design: Create products that are easily disassembled for repairs, refurbishment and recycling.

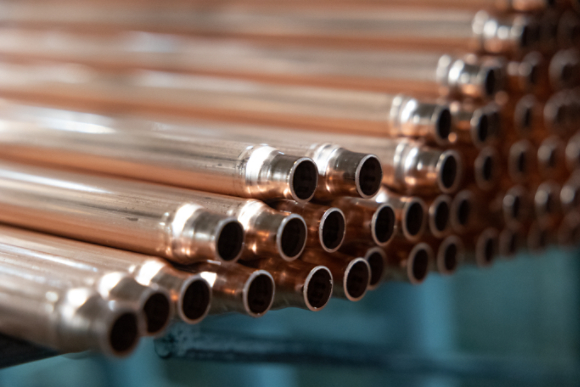

- Material Selection: Procure materials with low environmental impact through incentivizing a circular supply chain.

- Maintain, Prolong, Share: Keep products and materials in use by extending their lifespan for as long as possible..

- Reuse, Redistribute: Utilize a product or component on repeat, for its intended purpose without significant modification.

- Remanufacture, Repair: Return product or components to good working order through upgrade, repair, refurbishing or replacement to return to usable and intended state.

- Recycle: Transform a product or component into its basic materials or substances and reprocess them into new materials.

Learn more about our approach to designing for circularity and life cycle planning.

English

English