October 28, 2025

Rebuilding The Future: The New Circularity Blueprint

Season 5 Episode 10: Transforming how we think about the product lifecycle – even for buildings – to create a more sustainable future.

The world is waking up to a new reality: recycling alone won’t fix our waste problem. To build a truly sustainable future, we need to go circular - rethinking how we design, use, and recover the materials that shape our lives. We can beat the endless downcycle by designing smarter, innovating materials, and even dreaming up new consumption models. This isn’t recycling 2.0. It’s the blueprint for a new economy, one that preserves value, reduces strain on natural resources, and transforms waste into opportunity.

A new circularity definition

In this episode, hosts Scott Tew and Dominique Silva are joined by Jenelle Shapiro, Circularity Leader at Trane Technologies; Julia Gisewite, Chief Sustainability Officer, and Nelson Russom, Waste and Circularity Program Manager, both at Turner Construction Company. Together, they explore how circular design is reshaping everything from manufacturing and supply chains to construction and the built environment, and why collaboration and innovation are key to keeping materials in play, not throwing them away.

- Every year, the world throws away over 2 billion tons of waste. By 2050, the number's expected to be 3.5 billion tons of waste. And the impact is massive, rising emissions, polluted environments, damaged ecosystems. We recycle, of course. But does it feel like it's enough? Probably not, because recycling alone is not going to fix this. We have to go circular.

- Circularity isn't just about diverting waste, it's about preserving that value of that material, right? So we don't wanna extract more from our Earth, and we wanna just maintain what already exists today. So shift away from, you know, the questions of, can it be recycled, which is maybe the normal way of thinking about things, to instead think about, can it retain its original value after use?

- With traditional recycling, every cycle chips away at the product value and inches it closer to landfill, no matter how hard we try. But circularity tells a different story. We can beat the endless downcycle by designing smarter, innovative materials, and even creating new consumption models. This isn't recycling 2.0, it's the blueprint for a completely new type of economy.

- You're listening to "Healthy Spaces," the podcast where experts and disruptors explore how climate, technology, and innovation are transforming the spaces where we live, work, learn, and play. I'm Scott Tew, sustainability leader at Trane Technologies.

- And I'm Dominique Silva, marketing leader here at Trane Technologies. On season five of "Healthy Spaces," we're bringing you a fresh batch of uplifting stories, featuring inspiring people who are overcoming challenges to drive positive change across multiple industries. We'll explore how technology and AI can drive business growth, and help the planet breathe just a little bit easier. Hello, Scott.

- Hey, Dominique.

- So what are we getting into today?

- Let me ask you a question. What's the first thing that pops into your mind when I say, "Circularity?"

- Easy, three Rs, reduce, reuse, recycle.

- Yeah, that's what a lot of people would say. That's not wrong, but in reality, it's only part of the picture.

- Hmm. You know what, Scott? It does sound pretty reductive. I mean, yes, I can reduce the number of plastic bags that I use, I can repair my old bike and use it again, and I can probably recycle all of those dog pictures I printed it out at some point, but there's no way I could reuse my old PC from the '90s. And I'm pretty sure you can't recycle something like a car or even a building.

- Well, Dominique, don't be too hasty, because our guests in this episode are going to share a few things that are going to blow you away.

- All right, I'm ready. Let's not waste any more time.

- I'm gonna start putting a quarter in a jar every time that you make a bad pun.

- Ouch.

- So let's kick things off. We are diving straight into the heart of circularity. We're gonna talk about material value, the product lifecycle, with our very first guest, Jenelle Shapiro. But you have not heard it told like this before.

- Thanks, Scott. Thanks for having me today. Really look forward to the conversation. I am the circularity leader for Trane Technologies. And, you know, my role really is to help increase our offerings, circular economy offerings, as a business. What opportunities do we have to scale? How can we influence the HVAC industry and beyond to be kind of the subject-matter expert and the premier builder for circular systems?

- Well, do you know, you've already used the word, the big word, circularity, several times in the description of what you do. And maybe a lot of our listeners think they understand circularity. I'm sure somebody that has circularity in their title probably has a different view of circularity. Tell us what yours is.

- Yeah, I would say, you're right, right? In most cases, many people use the typical reuse and recycling terminology.

- We all love thrifting, you know?

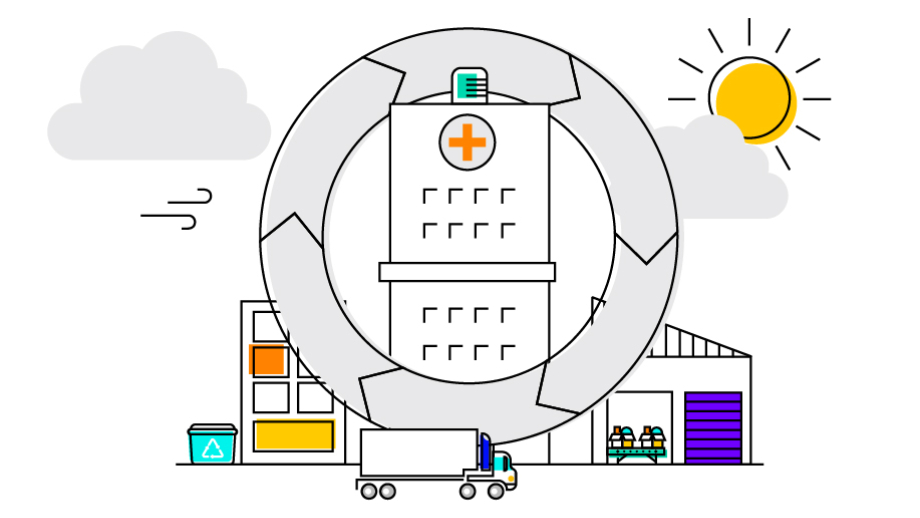

- Exactly. So those two Rs, as we call them, the Rs in kind of the circular economy, they are the best known, but I would say they're not necessarily the most important. I think what's really important is we kind of first define the opposite of circularity, right? So a linear model. So the opposite is, you know, in high consumerism-based culture today, products are, you know, made and manufactured, some product is used, and then discarded in a very quick timeframe. So the alternative, right, is a circular economy. So transforming the way we think about materials, products, equipment throughout the entire lifecycle stages.

- Even for a building, something as complex and as long-lasting as a building?

- Even for a building. And so, if you will bear with me, I'm happy to walk through kind of a hypothetical, you know, scenario. Let's think about the year of 2000. Let's say one of our partners built a new hospital-

- Yeah.

- In California. Generally, right, to build a chiller, we still needed the same raw materials. We needed steel, copper, aluminum, a compressor to kind of, and the core, heart, and the function of the build, that system, and heat exchangers. But let's say, fast forward, 10 to 15 years have passed, and the system ages, right? Just like our body ages, perhaps the, you know, the heart of the chiller, which is the compressor, may experience some type of, you know, wear. And maybe the hospital owners might be concerned that they need a new chiller, but, you know, that's obviously a quite expensive capital investment.

- Yeah. Obviously, they have to find the money, right? So, and the system's done though, right? It's over.

- Ideally, no, right? So just like you would do ongoing maintenance to your car at regular intervals, a chiller can be maintained to extend their useful life. So remanufacturing, as an example, could be something that may be necessary. It kind of goes with the saying of, you know, you don't throw the wine out with the cork, right? We're not gonna throw the whole system out at this given moment. So we think of it in the same kind of methodology, right? We find the good, and repair and refurbish those core pieces, or remanufacture the old, to really minimize any unnecessary wasted replacement. And now, you know, what's great about this is that the hospital can maintain its system for many more years in a circular way.

- You're really prolonging the life of the system, right, through things like you mentioned, servicing, maybe replacing old parts with new parts to keep it going. But that doesn't last forever, does it?

- Unfortunately not, right? A car, a chiller, a piece of clothing, at some point, does have an end. Really recovering equipment responsibly, I think, is the best alternative. And the customer, you know, has the ability, right, to ensure that the greatest value of the existing materials found in those systems that they have at their facilities, and the core components, can be salvaged, they can be reused. The refrigerant, right, is a big piece of that. How can that be reclaimed and sent to a recycler? And really the remaining scrap of those metals are recycled back in, you know, a closed-loop fashion. So I think, at that point, end of life, that's really what's essential to think about.

- Yeah, so we come full circle now, Jenelle. So I loved your story, taking us back 25 years, but here we are, the year 2025, already thinking about the year 2026 and beyond. How does circularity now fit into a company's forward strategy in the year 2025?

- I mean, I think it first starts with products and the way that we build our products, right? And what's really important, you know, stat that I've heard for quite some time, and for our viewers to understand, is that 80% of equipment's emissions are impacted and determined at the point of design. So this means that us, as an OEM, you know, an original equipment manufacturer, that we have that responsibility, right, to ensure that our HVAC designs take into consideration circular approaches, that we use less, we use again, and we really try to maximize the true value of the materials that we put into our equipment. And I think the most essential stakeholders, I would say, that are key to this kind of, you know, for success, right, and during the design phase, are engineers, the product management teams, any type of materials and chemistry or R&D teams of an organization, I'll say that I vision circular design kind of in three distinct buckets. First is the materials, right? What are you designing, and what are the products, what are you putting out to market, and how you can ensure that they have less resilience on virgin materials? You know, instead, how can we use higher recycled content or renewable inputs? Second is services, right? Maybe you might not think of this as business, but how do you design your products to ensure they're durable, they're repairable, they can be remanufactured, and build that, you know, added, well, let's say, you know, business value and business model for an organization, that's really key. And then I'd say the final step is the adoption accelerators. How can you, you know, strengthen the infrastructure, strengthen partnerships and engagement with third parties to, you know, ensure feasibility of collecting and recovering the high-valued materials and components at end of life?

- So you're talking, Jenelle, about, I guess, what we would call embedding this concepts into a company's value chain, or how they do their business. So for listeners out there with other companies, who may be small companies, medium companies, maybe large, complicated companies, what advice would you give if they're just thinking about these concepts?

- You gotta start somewhere, and you gotta start thinking about, again, what do your customers manufacture? You know, in many cases, customers have their own decarbonization roadmaps and goals. I think it really requires, you know, a mental mind shift within an organization, right? Identifying who the key stakeholders are within your own organization, and ensure that they're familiar with, you know, at each phase of our product's lifecycle, how they can influence and look at the full system and potential, and influence changes that will result in, you know, upstream and downstream impacts, really.

- Hey, Jenelle, there's this concept of end of life. I mean, you've mentioned these systems, and you keep them going forever, but you also mentioned that at some point, things do come to an end. It seems like a tricky topic though, because a lot of our lifestyle is built around us just discarding a lot of stuff. But manufacturers of big systems, like the ones that you're talking about, I mean, what's happening there at this end-of-life topic? How do manufacturers think about this?

- As a manufacturer, there's kinda three channels that we most clearly can influence. And so first, it starts, really, with our manufacturing facilities, right? We receive a lot of packaged goods at our plants. And through partnerships with our suppliers, you know, we've been been able, right, to redesign much of this packaging to create reusable alternatives, and really send back some of those in the reverse logistics channels. And then also at our manufacturing plants, we generate scrap, right? There's a lot of production process that has byproducts related to the machining and punching operations. So, you know, our EH&S and procurement teams, they are redirecting that scrap back to our tier one suppliers, which, in turn, increases, you know, raw scrap market supply, it increases our supply chain resiliency of the critical raw materials.

- Yeah.

- It also, you know, validates and creates that kind of trust and loyalty with those partners, which I think is, you know, really imperative. Second, really, is, how can we reuse the core components during the operational phase? So I talked a little bit about this in my hypothetical, you know, hospital, right?

- But as our equipment-

- Right.

- Maintenance, and overhaul process, you know, we provide the option to our customers to remanufacture. And basically what remanufacturing means is that you're taking a system, a core component, and in our case, a lot of times, this is our compressor, and you're breaking it down and disassembling it, really, to the bolt level. You're cleaning it, you're repairing it, and then you ultimately put that back together.

- It's like a heart transplant, right?

- Exactly. And, you know, what's great is that remanufactured products, they can offer that same performance as new ones, but they have lower cost barriers, right? Typically, lower environmental footprint. And so our customers are actually starting to see that value. They want to buy a remanufactured component. And I would say that, let's say the final phase of end of life is recovery, right? So, you know, what we're doing is we're buying back those systems. We're feasible. We're retaining that value of the systems long-term in kind of two channels. So our rental org absorbs those full pieces of equipment, and if they have more life to live, they refurbish those systems, and then they reintroduce it into their rental channel. And then the other way that we're doing that is through some of our EMEA markets, or our European markets, we're partnering with recycling companies to really disassemble the systems, and then reuse parts we're able. So they're giving, you know, rebates and financial return to our customers in exchange for these systems to ensure that we're using the right channels, redirecting the scrap in an appropriate and, you know, effective way to reuse the materials as much as possible, again and again.

- So, Jenelle, you mentioned a lot of things around this, and it seems commonsensical to me, you know, common sense that we're just gonna keep reusing things. And so there has to be something, something important here that nobody's talking about. What is it?

- I think one thing that maybe most people don't know is that a lot of recycling today is actually being downcycled. So what that means is high-quality, valuable materials, they're turned into lower-grade secondary applications. And circularity isn't just about diverting waste, it's about preserving that value of that material, right? So we don't wanna extract more from our Earth, and we wanna just maintain what already exists today. So shift away from, you know, the questions of, can it be recycled, which is maybe the normal way of thinking about things, to instead think about, can it retain its original value after use?

- Oh, it's a very different question.

- Very different. And, you know, a application or a challenge that comes to mind, I would say, in our own businesses, right, we utilize less common aluminum alloys to meet certain and very technical performance specifications. Things like thermal conductivity, heat transfer, and other specifications are necessary for some of our heating and cooling systems. That's essential, right, to develop a product that functions properly for our customers. But what's also essential is to ensure that we're not downcycling that material at end of life, or how can we recover that in the best viable option? So, you know, with processes, and where we're optimizing recycling, engaging with the right business partners and recyclers to evaluate capabilities, and how this scrap that we generate at our manufacturing plants, or that we recover at end of life, how, at the alloyed level, certain technology advancements can help to enable returning that aluminum into an actual HVAC system, versus returning that aluminum into, let's say, a, you know, a can that you would drink pop out of, right? So I think that's really the essential kind of key here, is that how can we redesign our systems and our infrastructure with our partnerships, and the third parties, to enable these efforts to ensure that, you know, we're seeing the economic value, the environmental value, as well as making decisions that will hopefully transition us away from this kind of more traditional recycling infrastructure?

- Yeah, I like that. Thanks for this. Thanks for mentioning the difference between what I think most people are thinking about, and where we may need to go next. Which brings me to this question around just sort of a crystal ball moment. So what is the game changer here related to circularity? Do you have a thought on what will change the game?

- I think one of the things to think about, and what might change this kind of nomenclature around circularity, is looking at the existing building stock we already have built today. I think that's really key. And how can we harvest buildings and systems already in operation? So viewers may or may not be familiar with The Circularity Gap Report. This is a report that's put out by Deloitte in the circular economy. And basically, this previous year, it indicated that more than 100 billion tons of materials are consumed annually, but only 6.9% of that material is actually cycled back into the economy. Meaning a vast majority of materials entering the supply chain are virgin. But, you know, we have a potential, and a circularity potential, right, to improve and utilize harvesting of these materials that already exist and we're using. So, you know, our systems are large, right? When they're ready to be disassembled and recovered at end of life, it requires really significant technology advancements. And so I think, really, the future lays in technology, I won't use the word AI again, but what I will say is that there's some new horizon technology related to automated disassembly and other types of software tooling for dismantling its systems in a more effective way. And ultimately, I think this will also help us shift and see the opportunity reducing supply chain risk, price volatility, and other type of risk-related impacts that businesses like ourselves and others might see. So technology is key here. And I think there's a lot of horizon opportunities that will help to enable our recovery and recycling of the existing building stock.

- So far, we've heard a bit about the theory of circularity, and how we're approaching it at Trane Technologies, but I'm glad to say we're not the only ones that are thinking about this. Our next guest are Julia and Nelson from Turner Construction Company, which is the largest green builder in the United States. Turner's on a mission to decarbonize construction, which means that the circular model is a non-negotiable.

- My name is Julia Gisewhite. I am chief sustainability officer at Turner Construction Company. What that means, in every day what I do, is thinking about the strategy, sustainability at Turner, and implementing sustainability across 15,00 projects every day, touching 100,000 workers every day, and working in and amongst the networks of sustainability professionals who are boots on the ground, and deploying our strategy every single day.

- Nelson, tell us a bit about yourself.

- My name's Nelson Russom. I manage Turner's Waste And Circularity Program. So really kind of developing the organizational strategy as it's related to those topics, but that also includes interfacing with our clients and project teams about specific opportunities or challenges they may have, as well as interfacing with other industry partners to progress the available practices.

- Julia, I thought I'd start with you. This conversation, as you mentioned, is about circularity, a concept that maybe a lot of our listeners think they understand. You know, a circle, we all get the shape. So circularity is a concept, though, in terms of construction. I mean, what do you think that people get wrong about this concept of circularity? Let's start there.

- Yeah, I'd say that circularity sounds super intuitive. Like reuse, recycle, keep things in the loop, right? That's what we think of. But I think the biggest misconception is that it's just about materials, like turning construction waste into something else, or aggregate, or reusing bricks on sites, things like that. But it's not just about recycling. And I think circularity is more of what we call a systems mindset. And what a system mindset means is looking at buildings, or the way we build buildings, as not just as isolated parts, but as very interconnected, very dynamic, understanding how things influence each other, sometimes in complex ways. So we can think about that in terms of the way we build, we can think about it in terms of companies, you know, being systems. And I'd like to use the analogy of LEGOs and Jenga towers, and so I'm gonna explain this, explain what I mean. So with LEGOs, everything is modular, right? It's designed to snap together, and they can come apart easily. And all that flexibility makes it easier to reconfigure and repair, and expand whatever you're building. But when you have Jenga towers, Jenga towers are very rigid, and they might stand up for a while, but they're actually very inherently unstable. And so you pull one piece out, and you risk collapsing the whole thing. So I think when we talk about circularity in construction, we wanna think more about doing it in terms of the LEGOs, using materials that can be reused, and adaptable, and traceable, and designing for change, and building in a way we can keep reworking and changing, and improving over time.

- Maybe some listeners think that, or they're assuming that some of this effort is about trying to meet some kind of changing regulations. Like we know for us, for instance, that some cities and countries, they wanna cut down on things that are landfilled. In your view, over 20 years here, is this all about trying to react to a regulation, or is it something more than that?

- No, I think we've seen an evolution, and I think there's more awareness now around carbon, number one, and the way material flows, number two. And I think we see, we're able to map a little bit more of that material flow. But you're right, there absolutely has, there's a mindset shift that's happening today. Two decades ago, we were in a very linear mindset. It was build it fast, build it cheap, and toss out the waste, right? And waste, no one cared about waste on projects unless it affected the schedule, right? At Turner, we've been tracking our waste, I'm looking to Nelson, maybe 15, 20 years. As a company-wide initiative, it was supporting this growing portfolio of lead projects that we had. So we actually have a lot of data, going back many, many years, on the waste profiles of our projects. But the infrastructure, the opportunity, the ambition to address that waste just wasn't there. But, you know, we are seeing deconstruction pilots, we are seeing reclaimed material markets, we're seeing digital twins for tracking materials and assets. We are in a different world. It's still early days, but a lot of progress, and a long way to go.

- Is that what you're focusing on now, Julia? I mean, you just mentioned sort of a siloed approach historically, versus this design or systems approach today. So tell us about that. What are you focusing on now at Turner related to this new way of viewing a design and planning phase?

- Yeah, so we have shifted to a less siloed way of building. So what used to happen is architects, engineers, MEP engineers, facilities, teams, all passing the baton very linearly from one person to another, one entity to another. Our contracts were set up that really kind of made it that way for us. Circularity can't work in that model. There needs to be integration from day one. And I think we are seeing that type of de-siloing happen early in the design.

- Let's talk about that then, Nelson. I mean, Julia just mentioned the importance of sort of working together on a design and planning arena, but what about managing waste on site? I mean, what's different today versus 10 years ago?

- Yeah, I think not too dissimilar from 10 years ago, as you said, waste is hyper-local. We really work with our teams to develop their waste management plans to understand what materials can actually be diverted that are local to them, because as embodied carbon is always there, the emissions associated with transportation of materials is a factor and is something that gets weighed. But I can say that where we're focusing now is prioritizing the use of more durable materials in our own operations. So I often think about the years where I would see a shaft opening, and there would be a two-by-four assembly, stick-built, with a boot that would protect us from anything kind of going down that shaft. And at the end of that installation, it would come out, maybe it would be installed again on that project, but eventually, it would make its way to a dumpster, unfortunately. And where we're looking is utilizing systems like metal barricades that perform the same function, but can be removed, reinstalled time and time again, and even on multiple projects. That really minimizes the waste associated with them, and really preserves that wood to be used for more practical applications.

- I love that type of innovation, Nelson. Is there a project, do you have in mind, or a customer that you could provide to the listeners, an example of, that you think is really creative and that's working?

- The thing is, something we haven't talked about much here, where we've had a lot of successes is actually in donation of existing materials. We have a couple of projects that come to mind, a student housing project for a higher education client in Boston. They had, in addition to the refresh of their dorms, they had some appliances that were reaching the end of their warranty, and the intent was to return them to the organization that they bought them from, who would then recycle them. And our team actually proposed the idea of partnering with a local entity, who was able to make those units available to historically underserviced and underrepresented communities, who may not be able to buy a brand-new refrigerator or other appliance if theirs were to go down. And that was a way for us to kind of tie our client into their community.

- I love it. It's like thrifting for buildings, right? It's like repurposing.

- Yeah, absolutely.

- Julia, I spend a lot of time as a sustainability leader myself with other sustainability leaders. One thing we have in common is that we typically are working on 10 things at once, but I know for a fact that circularity has to fit into something broader for Turner Construction. So how does it fit in with all the other themes that you are working on as a company?

- I would say one of the big things that we're working on as a priority across the organization, not just within our sustainability program, is supply chain. You know, we do have all of these ambitions at Turner. And supply chain, I think, for us is going to be a huge lever, has become a huge level for us. And of course, carbon reduction, because, you know, Turner has ambitions, but we don't achieve our environmental ambitions without bringing our value chain along with us, and they evolve with us. So, but where I also see our supply chain as a lever for innovation, and for this topic of reuse, because I think our value chain, actually, Nelson, you know, it's where circularity begins. You know, before we can reuse anything, before we can reduce anything, or keep materials in the loop, you know, we're gonna have to ask, "What are we buying, where is it coming from, how's it being made, what's it made of?"

- Yes, what's being sourced? What are we actually, what are we sourcing from those suppliers, right?

- What are we sourcing? You know, so supply chain is how, you know, determines what shows up on our sites. And it also, that's upstream. Downstream, it's what happens after. We are a, Scott, I'll add, we are starting to embed circularity into our bid processes. So we are asking suppliers about, you know, do they offer take-back programs? What is their reuse/recycle content? And then asking about things like packaging, zero-waste programs. So then Nelson also mentioned some formal partnerships we have with suppliers, who can offer those to our projects at scale.

- Yeah, Julia, in a recent conversation that we had on some of these topics, you mentioned that you were also working on sustainabilities for the people, getting your own people engaged. So how do you do that within Turner? You have a recipe that you wanna share with our listeners?

- I would say that maybe in circularity, and the work that Nelson's doing at Turner, maybe more than any other of the topics in our sustainability program, our people really wanna engage with it. So the more, you know, that we can maybe avoid the top-down mandates, but arm people with information, give them the context and the tools. A lot of the most effective ideas come from people in the field who see opportunities that I don't, or that Nelson doesn't, right? And so when we create space for that grassroots initiative to happen, I think we ultimately find solutions that are more long-lasting, and they actually apply to, you know, the real-world, real-time challenges that we see on job sites.

- So circularity is one thing that you guys are working on. What other big sustainability commitments or themes are you also focused on?

- When you look at our purpose, Scott, as a company, Turner's purpose is to make a difference in the lives of our people and our customers, and our community. And so we've built this ESG strategy, this group of commitments, that's focused on being very intentional and being very future-focused on these things. So we are one of the largest players in the sector. And we have the ability, and quite honestly, the responsibility, to move the needle on the things we're doing around the environment. One of our core emissions is carbon reduction. We have aspirations to be net zero across all of our reporting scopes by 2040. And to do that, we are prioritizing reductions at the source, where the emissions happen on our site. So we are electrifying fleets, looking at low-carbon materials, alternate fuels, energy management, storage renewables. But circularity is a tool in this toolbox for us.

- Sure.

- And it directly connects to our carbon goals. You know, what happens to the buildings that we build at the end of their life is, squarely sits in our scope three. But I would add, all that, we're putting a lot of blood, sweat, and tears into chasing that net-zero target. But our sustainability work isn't just about carbon, and it's not just about materials, it's, at its core, about people. And at Turner, you'll hear the term active caring a lot. And what that means is making sure that all of our team members and those that work on turner sites feel valued, feel supported, and feel like they can come in their best form every single day. So you'll see at a Turner, it shows up everywhere, it's from how we prioritize mental health, site safety, how we engage communities, and it shows up in how we rethink about what buildings can do for people over time. So when you start putting people kind of squarely in the lens, you start asking better questions "So are materials safe? You know, what design choices can we make that reduce health? Can we improve job site conditions during extreme heat?" So I think all of that is starting to, there's a lot of synergy with other work that's happening, you know, tangentially to the sustainability department, and showing up on our project sites.

- Yeah, Nelson, none of this happens without the people at the project sites, right?

- For sure. And I think it's, as much as we're on the precipice of circularity becoming much more front of mind in our conversations around sustainability, we're very much at an education point, not only with our clients, who are starting to use some of these kind of hot-button words around zero waste and things like that, but also understanding that we have to educate our project teams and the trade partners who are on our projects about these concepts, and what little shifts are gonna be necessary to actually be able to make these things real. And I think that's engaging with them. As Julia said, active caring is sometimes just checking in, but also understanding that they have the knowledge of the years of practice, and do they understand where the waste is in their operations, but they may not have had the willingness or the power to be able to make a suggestion about something. And some of our most successful practices have been when these conversations come up, and these ideas come from the trade partners themselves. And I think that's a really exciting point of time to be at.

- So Dominique, did that clear everything up for you?

- Okay, Scott, you did it. It sounds like you can recycle a building if you know the value of each of its components. And I love that perspective shift that our guests brought today. We absolutely need to reduce our reliance on virgin materials, but we also need to actually look at what's right in front of us, understand the value of the product, and then find ways to maintain that value.

- Yeah, I mean, what stood out for me was hearing that yes, we all share a role in minimizing waste, but a product's ability to be recycled depends so much on the design stage. That means that manufacturers have a responsibility to make sure that their output is fit for a circular economy. It also means there's so much space for innovation.

- I know, it's really exciting. And this idea that we can effectively harvest buildings is kind of a revelation for me. It's like we discovered a new material resource right under our noses.

- That's a great way to put it. I think that what I'd like to ask our listeners this time is this question, how are you thinking about circularity in your buildings, whether it's your home, your place of work, or even a construction site, what ways are you keeping waste down and material longevity up? Leave us a comment, and let us know. That's it for this time. This has been the "Healthy Spaces" podcast with me, Scott Tew, and my co-host, Dominique Silva. To learn more, check the links in our show notes. Wanna stay on the front line of innovation and sustainable growth? Subscribe to "Temp Check" newsletter on LinkedIn. Stay in the loop. We'll be back next week with the final episode of the season. So be sure to like and subscribe, so you don't miss out. Thank you for joining. We'll see you next time.

Featured in this Episode:

Hosts:

-

Marketing Leader EMEA, Trane Technologies

-

Global Head and VP, Sustainability Strategy, Trane Technologies

Guests:

-

Sustainability and Circularity Leader, Trane Technologies

-

Chief Sustainability Officer, Turner Construction Company

-

Waste and Circularity Program Manager, Turner Construction Company

About Healthy Spaces

Healthy Spaces is a podcast by Trane Technologies where experts and disruptors explore how climate technology and innovation are transforming the spaces where we live, work, learn and play.

This season, hosts Dominique Silva and Scott Tew bring a fresh batch of uplifting stories, featuring inspiring people who are overcoming challenges to drive positive change across multiple industries. We’ll discover how technology and AI can drive business growth, and help the planet breathe a little bit easier.

Listen and subscribe to Healthy Spaces on your favorite podcast platforms.

How are you making an impact? What sustainable innovation do you think will change the world?

Topic Tags

English

English